+86-136-0125-0542

(Whatsapp/skype/facebook above)

+86-10-5791-9571

follow

pipe diameter:φ 50mm --φ 4000 mm, pipe length: 12000mm

Telephone :+86-136-0125-0542Filament winding machine is designed for the production of fixed-length FRP pipes, pure FRP pipes and FRP pipes filled with sand. The pipe diameter ranging is from DN 50mm to DN 4000 mm The machine is suitable for high pressure and low pressure pipes (according to the type of joint design).

Main application FRP pipes:

Mainly used for transportation of chemical materials,drinking and sewage water, recycling water in power plant.

Our Advantages:

1. Winding carriage of liner making machine is equipped with a resin-feeding system and a spraying head, it is not required hand lay-up to make the pipe liner.

2. This winding mode can be directly shifted between hoop winding and helical winding from both end of the mandrel;

3. The resin content in sand layer of the pipe is controlled by the computer, and can be kept as low as 15-17%;

4. Efficiency of resin spraying system is up to 45kg/min.

5. Sand layer thickness can be maximized up to be 20mm in one time, while the stiffness of the pipe is guaranteed.

Production lin specification:

-DN50-300mm*L6000mm

-DN300-2000mm*L12000mm

-DN300-2600mm*L12000mm

-DN2600-4000mm*L12000mm

(DN-pipe nominal diameter, L-pipe length)

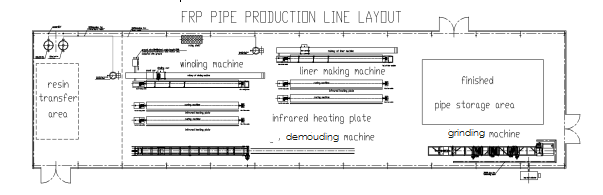

The Production Line is composed by the following equipments:

1. Liner making machine

2. Filament winding machine( with sand dosing system)

3. Resin mixing systerm

4. Curing machine

5. Demoulding machine

6. Grinding machine

7. Hydrostatic testing machine

Technical specification:

1. Available pipe length:0-12m

2. Winding angle:45°-90°

3. Winding pattern:Helical and hoop, auto exchange

4. Computer control mode: Manual,semi-auto and auto.

5. Sand filling method: sand preming technology, sand laminating technology.

6. FRP pipe production standard GB/T- 21238

Processing Description:

To produce the chemical resistant liner on the rotating mandrel with fiberglass surface mat, resin, stitched mat etc.on Liner making machine → 2.Curing of the finished liner of the pipe with mandrel on the curing machine → 3.To produce the structure layer of the pipe with fiberglass roving , resin and sands (as filler) on filament winding machine → 4.Curing of the pipe with the mandrel on the curing machine → 5.Grinding the joint groove at the end of the pipe with mandrel on grinding machine → 6.The pipe is extracted from the mandrel on demoulding machine → 7.Testing of the pipe

FRP pipe production line layout