+86-136-0125-0542

(Whatsapp/skype/facebook above)

+86-10-5791-9571

follow

For producing GRP profiles in different shapes

We also supply pultrusion lines of reinforcement rebars /window profiles / wind turbine blades / sucker rods and crawler-type pultrusion line.

This machine is suitable for producing GRP profiles in different shapes, like angle sections, “C” channels, Hollow rectangular and circular-tube sections, solid rods, etc. Pultrusion profile is based on fibers that are impregnated with a thermosetting resin and pulled through a heated die where curing takes place. Different laminate lay-ups are possible with reinforcements of roving, mats, fabrics and multi-axial. The finished profiles are cut to length by a saw at the end of the line.

Our Advantage:

Closed loop electro hydraulic speed control with feed-back is standard on all reciprocating machines and ensures constant pull speed.

In line transducer constantly monitors pulling speed indication digitally.

The machine is easy to maintain and operate, reliable and consistent in quality, it is the ideal machine for industrialization production

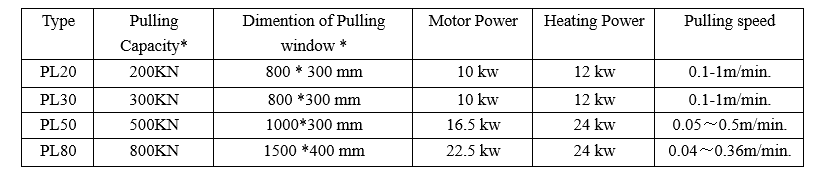

Specification:

The parameter with * mark can be customized by demand.

Processing description:

The process starts with the support of the reinforcements. These can be glass, carbon or aramid and in a roving/tow, mat, woven or stitched format. The material is pulled into the infeed area where it is accurately formed to the required shape and impregnated with resin. The resin can be polyester, vinylester, epoxy or phenolic. From the infeed area the impregnated reinforcement is pulled into the heated pultrusion die. The resin is heated and cures within the die. The cured profile exiting the die is allowed to cool before being clamped and pulled by the reciprocating puller units. The puller units reciprocate in a 'hand over hand' motion, with the return stroke being faster than the pulling stroke' to give a smooth continuous pull at a constant speed irrespective of the pulling force required. From the puller units the profile passes into the pneumatic cutting saw where it is cut to the required length.

The Production Line is composed by the following equipments:

1.Creel

2.Impregnating device

3.Forming table

4.Traction machine

5.Cutter

6.Product collection table

Dies can be designed and produced according to the requirement of the customers