+86-136-0125-0542

(Whatsapp/skype/facebook above)

+86-10-5791-9571

follow

The hydraulic composite forming machine is up to 5000 tons.

Telephone :+86-136-0125-0542The hydraulic composite forming machine

The hydraulic composite forming machine is up to 5000 tons, which are widely operated for SMC,gmt,D-LFT and carbon fiber fiels.

Our advantages :

• Processing complex shapes and geometries

• Parts with a small thickness

• High surface quality on both sides.

• Four-column or frame structure,

• Digital control,

• Closed system for maintaining pressure and energy-efficient function,

• Function of multiple prepressing and air discharge,

• Multiple pressing and automatic control of air release,

• Function of non-pressure targeting of the mould, function of detection of malfunctions,

• Complete safety mechanism and safety control system,

• Highly efficient water cooling unit will satisfy continuous production,

• Heating mode: steam heating / electric heating / oil heating.

Various expending function including:

*Short or long stroke parallelism system

* Auxiliary hydraulic and pneumatic circuit

Parallelism control system

Servo directly driven technology is widely furnished for composites machine, there are tremendous noise and power consume with this new technology.

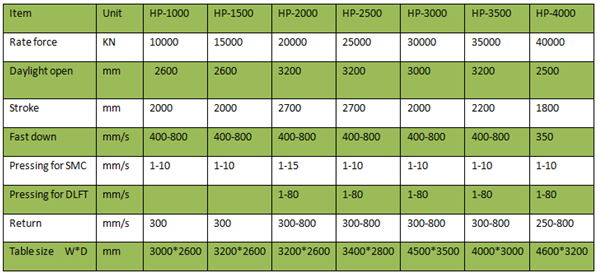

Main data for D-LFT and SMC press:

We have a large experience in SMC forming process, the servo driven control technology brings a lot of advantage including the tremendous noise reduction power consume reduction, the structure of the forming press can be both straight side or 4 post style.

Standard and basic features of composites presses are as follows:

Rigid press frame with four face 45 degree heat compensation guiding

Individual tooling scrap cylinder for tooling opening.

Various heat system including electric, thermo oil or steam system are available as per client's requirement.